Cities around the world are facing a growing challenge: how to manage increasing waste volumes efficiently while encouraging citizens to recycle correctly. Traditional containers often fall short. They’re bulky, confusing to use and make proper waste separation harder than it should be.

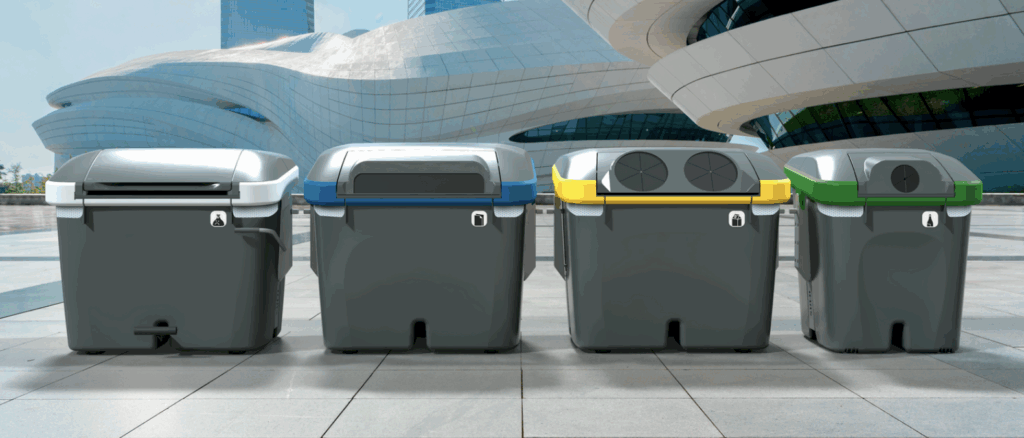

That’s where SULO’s NEXO side-loading containers come in. Designed with maximum capacity, ergonomic usability and intuitive color-coded lids, they make recycling simpler, faster and more effective for everyone.

For the manufacture of the containers, SULO contacted ABC Rotomoldeo with the aim of achieving a lightweight, ergonomic, and highly durable design, for which rotomolded plastic offered a competitive advantage.

What are NEXO side-loading containers?

The NEXO containers are redefining urban waste management. Available in 1,900L and 2,900L formats, they boast the highest volume-to-height ratio in the market, maximizing capacity while maintaining a compact, low-profile design.

Some standout features include:

- Optimized height (1,550 mm) for improved visibility and urban safety.

- Ergonomic loading with pedal and lever access from six positions.

- RFID-ready design for intelligent waste tracking.

- Braille labeling to ensure inclusivity.

- Modular components for easy maintenance and replacement.

According to SULO’s own catalogue, these containers are designed for citizens, cities and companies alike, offering a better balance between capacity, safety and sustainability.

“With NEXO, cities can manage more waste in less space while making recycling intuitive for everyone.” — SULO

Smarter urban solutions through advanced rotomoulding

In urban waste management, durability and performance are everything. Side-loading containers like SULO’s NEXO face extreme conditions every single day:

- Constant lifting by garbage trucks

- Exposure to UV rays, rain, and temperature fluctuations

- Intensive daily use by thousands of residents

For municipalities and service providers, this translates into a huge challenge: finding containers and components that can withstand harsh environments while keeping maintenance and replacement costs under control.

This is where rotational molding makes a difference. Compared to injection molding or blow molding, rotomolding offers clear technical and economic advantages for large-format components like container lids, covers, and structural parts:

- One-piece construction. Eliminates weak joints and potential break points, ensuring longer-lasting components.

- Lightweight yet robust. Reduces operational stress on garbage trucks, minimizing mechanical wear and fuel consumption.

- Superior durability. Highly resistant to UV exposure, impacts, and extreme weather, meaning fewer replacements and lower lifetime costs.

- Design flexibility. Allows for ergonomic shapes, seamless integration, and even customized branding if required.

- Cost efficiency. Lower tooling costs than injection molding and excellent scalability for high-volume production.

By leveraging these benefits, ABC Rotomoldeo produces large, high-performance components that help cities and waste management companies extend container lifespans, optimize operational costs, and reduce long-term maintenance expenses.

Results: where NEXO containers are making a difference

While SULO operates internationally, the NEXO containers have already been adopted in numerous European cities, particularly in Spain, France and Germany, where side-loading systems dominate waste collection.

ABC Rotomoldeo’s contribution has helped standardize modular replacement of lids, enabling cities to:

- Update or replace components without discarding entire containers

- Adapt color schemes as recycling norms evolve

- Extend product lifespan, reducing environmental impact

ABC’s central location in Spain provides logistical advantages for quick distribution across Europe and beyond, making them a key manufacturing partner in SULO’s supply chain.

More resilient urban solutions thanks to rotational moulding

ABC Rotomoldeo’s involvement goes beyond manufacturing; it’s about aligning with eco-design principles:

- Recycled materials integrated into the lids where possible

- Energy-efficient production processes via rotational molding

- End-of-life recyclability to close the materials loop

This synergy between design, durability and sustainability reflects the broader shift in waste management strategies: creating products that last longer, generate less waste, and make recycling effortless for citizens.

Why choose ABC Rotomoldeo as your strategic partner

At ABC Rotomoldeo, we specialize in developing custom plastic components through rotational molding, working hand-in-hand with companies, brands and public institutions to bring their ideas to life. Our goal is to deliver durable, sustainable, and visually distinctive solutions adapted to the specific needs of each project.

What do we offer?

- Over 15 years of expertise. We have extensive experience in large-format rotomolding, creating high-quality components for urban spaces, industrial applications, and branded products at an international level.

- Tailor-made solutions. Every project is unique. We design and manufacture fully customized components from lids, covers and structural pieces to special finishes, adapting to your technical, aesthetic and functional requirements.

- 360º service. Our process covers everything, from 3D design and mold creation to material selection, textures, color customization and integration of logos or brand elements.

- Flexibility and scalability. Whether you need thousands of identical units or short, highly customized production runs, our facilities allow us to deliver fast, reliable and cost-efficient manufacturing.

- Sustainability as a standard. We work with recycled polymers whenever possible and guarantee compliance with ISO 9001 and ISO 14001, ensuring environmentally responsible production.

Whether you’re developing urban furniture, waste management solutions, industrial components or custom-designed pieces for your brand, our team can help you transform your idea into a durable, efficient and fully customized reality.

Contact us and let’s explore how we can make your next project stand out.