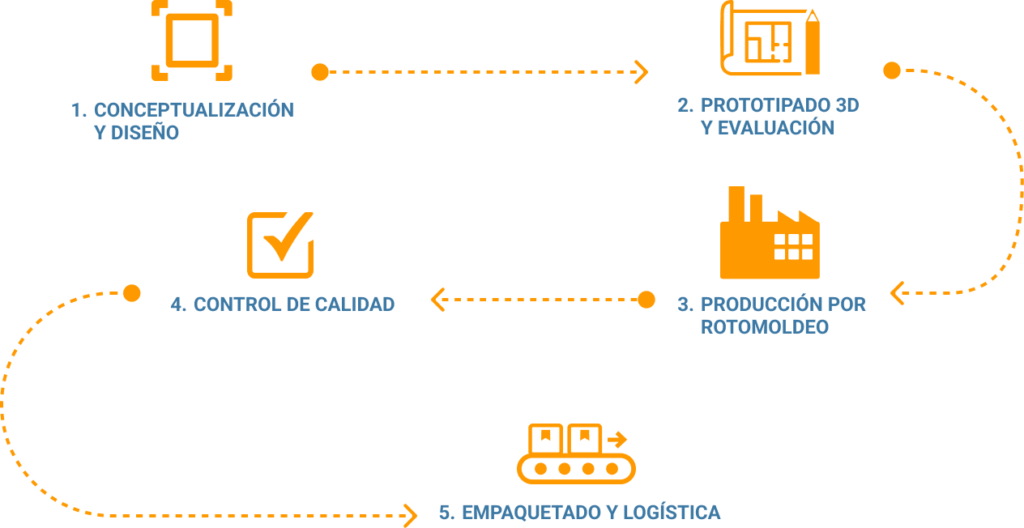

Rotomolding or plastic injection molding: differences, advantages and applications in the industry

In the world of plastic component manufacturing, the choice between rotational or injection molding can make all the difference in terms of efficiency, cost and adaptability. Both methods offer versatile solutions, making them fundamental pillars in industries