ROTOMOLDEO for automotive and aerospace sectors

ROTOMOULDING IN THE AUTOMOTIVE AND AERONAUTICS SECTOR

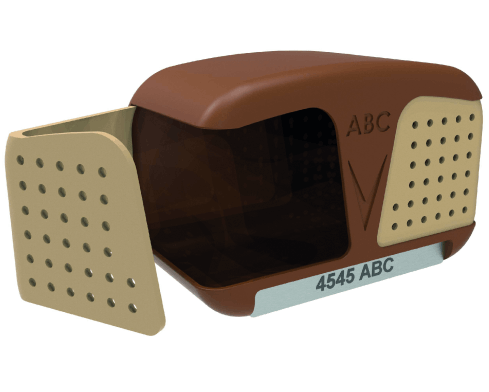

Rotomoulding can be of great use in the automotive and aeronautical industries, allowing the manufacture of highly complex parts and adapting to small and short series. In addition, rotomoulding allows the use of different materials, providing lightness, airtightness and durability to any component such as fuel or oil tanks, battery casings, interiors and exteriors, air ducts, etc.

The ABC ROTOMOLDEO team has the necessary experience and knowledge to satisfy the needs of these two demanding sectors, as demonstrated by the products we have been manufacturing for years and which are in service with several major brands.

ADVANTAGES OF ROTOMOULDING FOR THE INDUSTRY

LOW WEIGHT

CIRCULAR ECONOMY

NO OXIDATION

WATERTIGHTNESS

PARTS AND PROJECTS CARRIED OUT

Rotational moulding gives us a series of advantages that allow us to manufacture high quality products for the automotive and aeronautical sector. Rotomoulding in the automotive sector allows us to combine low weight and watertightness with 100% recyclable products, thus promoting the circular economy. We replace multiple components with a single part, reducing costs and facilitating thermal insulation. By working with plastic raw material, there is no oxidation, thus extending the life of the product and offering greater design freedom for interiors and exteriors.

Ask for more information about our rotomoulded products and other services.

You can also contact us on

(+34) 969 13 03 82

You can also contact us on

(+34) 969 13 03 82

ABC's CAPABILITIES

With over 20 years of experience, ABC ROTOMOLDEO is a leader in innovative solutions for the automotive and aerospace industries. Our highly skilled team fuses expertise and efficiency to produce lightweight, durable and 100% recyclable components. We excel in the design and manufacture of unique parts that reduce costs and extend product life, demonstrating our capability and versatility.