Rotational molded products play a critical role in modern plastic manufacturing, offering a unique balance between design freedom, durability and cost efficiency. Thanks to the rotational moulding process, manufacturers can develop hollow plastic parts with complex geometries, uniform wall thickness and excellent mechanical performance, making this technology suitable for a wide range of industrial and commercial applications.

As industries demand lighter, stronger and more sustainable plastic solutions, rotational moulding has become an increasingly strategic manufacturing method across sectors such as automotive, marine, logistics, leisure and liquid storage.

What are rotational molded products and how are they manufactured?

Rotational molded products are plastic components manufactured using the rotational moulding process. This low-pressure plastic manufacturing technique involves heating polymer powder inside a rotating mould, allowing the material to evenly coat the internal surfaces and form a hollow, seamless part.

Key characteristics of the rotational moulding process

- Uniform wall thickness, even in complex shapes

- No internal stresses due to the absence of high pressure

- Seamless, hollow parts with excellent impact resistance

- Compatibility with polyethylene materials such as LLDPE, HDPE and XLPE

These characteristics explain why rotational molded products are widely used in applications where durability, chemical resistance and long service life are essential.

For a detailed explanation of the process and its advantages, consult the Association Francophone du Rotomoulage.

Why choose rotational moulding for industrial and commercial applications?

Many manufacturers ask: Why use rotational moulding instead of injection moulding or blow moulding? The answer lies in the specific advantages this process offers for certain product types and production volumes.

Main benefits of rotational molded products

- High design flexibility without secondary operations.

- Lower tooling costs compared to injection moulding.

- Excellent surface finishes and consistent wall thickness.

- Efficient material usage with minimal waste.

- Strong, impact-resistant and long-lasting plastic parts.

These advantages make rotational moulding particularly suitable for medium-volume production runs, custom designs and industry-specific plastic components.

Rotational molded products by industry and application

Automotive industry

In the automotive industry, rotational molded products are used to manufacture automotive plastic components that require strength, lightweight construction and resistance to chemicals and temperature variations.

Common automotive applications:

- Instrument panel housings and technical enclosures

- Armrests and interior trim components

- Air ducts and fluid conduits

- Fuel and fluid tanks

- Traffic signs, safety barriers and road separation systems

Rotational moulding allows automotive suppliers to create durable components with complex geometries while maintaining cost efficiency.

Leisure and entertainment industry

The leisure and entertainment sector extensively relies on rotational molded products due to their resistance to outdoor conditions, UV radiation and mechanical stress.

Typical leisure applications

- Kayaks, canoes and leisure water equipment

- Toys and playground elements

- Outdoor and garden furniture

These products combine functional performance with attractive finishes, making rotational moulding ideal for consumer-facing applications.

Containers and reusable packaging

Rotational moulding is a preferred solution for manufacturing reusable plastic containers and packaging systems used in logistics and industrial transport.

Examples of rotational molded containers

- Aircraft containers

- Insulated boxes and refrigerated containers

- Barrels and industrial drums

- Planters and large-volume containers

- Reusable transport and logistics containers

The robustness and long service life of these products support sustainable and circular economy models.

Naval industry

The marine industry is one of the most established sectors for naval rotational molded products. Seamless construction and inherent buoyancy make this process ideal for water-based applications.

Marine applications manufactured by rotational moulding

- Recreational boats and small leisure craft

- Kayaks and canoes

- Buoys and floating safety elements

Rotational molded products used in marine environments offer outstanding resistance to saltwater, corrosion and UV exposure.

Liquid storage and industrial tanks

One of the most common uses of rotational moulding is the production of industrial plastic tanks and reservoirs for liquid storage.

Liquid storage applications

- Fuel and oil storage tanks

- Chemical storage tanks

- Septic tanks

- Water treatment and water storage tanks

- Agricultural tanks for fertilizers and irrigation

This could be interesting for you: Plastic rotomolded tanks: versatile applications for any industry

Rotational molded tanks are valued for their leak-free design, chemical resistance and long-term reliability in demanding environments.

Material handling and logistics

In material handling and logistics, rotational molded products help improve safety, efficiency and durability throughout the supply chain.

Logistics and handling applications

- Medical and technical cases

- Protective packaging

- Plastic pallets

- Special containers for internal logistics

These solutions combine lightweight design with high impact resistance, making them suitable for repeated handling and transport.

Rotomoulding in the defense industry

At ABC Rotomoldeo, we know innovation and defense go hand in hand. Our rotomoulded parts turn plastic into custom solutions: lightweight yet strong components designed to blend into any environment. They meet the sector’s complex demands, offering durability and reliable performance under extreme conditions.

Advantages:

- Impact resistant

- Lightweight

- UV resistant

Projects:

Our products feature impact resistance, fire-retardant properties, and camouflaging capabilities, ideal for military applications. Lightweight and durable, they can replace multiple components with a single piece, with UV protection ensuring longevity in harsh conditions.

Rotomoulding in industrial applications

ABC Rotomoldeo transforms industrial manufacturing with versatile rotomoulding solutions. We work with a wide range of materials to produce large, durable, high-quality parts tailored to client needs.

Advantages:

- Fire-retardant

- Large-scale components

- Multicolor options

Keep reading: Rotomoulding in the food industry: containers for high-pressure equipment

Projects:

We create industrial parts from PP, PA, PE, including fire-retardant and biodegradable options. Our technology enables unified designs that replace multiple components, reduce assembly costs, and deliver UV-resistant, long-lasting pieces in any color.

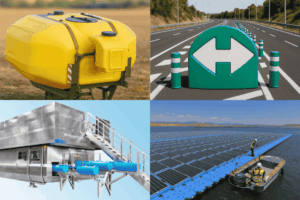

Rotomoulding in civil and construction projects

ABC Rotomoldeo adds value to urban environments with rotomoulded products made from virgin or recycled plastic. From formwork to signage and storage solutions, our materials ensure safety, durability, and aesthetic quality.

Advantages:

- UV resistant

- Multicolor options

- High durability

Projects:

Our innovative range includes formwork, signage, and waste management solutions designed for UV exposure. Robust and flexible, these products adapt to complex construction challenges, enhancing project efficiency and safety.

How to select the right rotational molded product for your industry

When choosing rotational molded products, manufacturers and buyers should consider several key factors:

- Required mechanical strength and impact resistance

- Chemical and environmental exposure

- Design complexity and part size

- Production volume and tooling budget

- Compliance with industry-specific regulations

Understanding these parameters ensures the rotational moulding process is applied where it delivers maximum value.

The role of rotational moulding in future product development

As sustainability, durability and design optimization become increasingly important, rotational molded products continue to gain relevance across multiple industries.

Their ability to combine performance, cost efficiency and design freedom positions rotational moulding as a strategic manufacturing technology for current and future industrial challenges.

ABC Rotomoldeo: from the idea to the delivery, customised manufacturing

ABC Rotomoldeo is the leading company in Spain specialising in the manufacture of custom-made rotational moulded products and components. The company supports its clients throughout the entire process, from initial concept and engineering to manufacturing and final delivery, always focusing on reliable technical solutions and high-quality results.

A significant part of ABC Rotomoldeo’s activity is dedicated to design, manufacturing and personalised quality control, ensuring a high level of finish, attention to detail and service.

Would you like more information about our rotomoulding factory or to know how we work?