In plastic manufacturing, choosing the right technique is key to optimizing costs, quality, and part functionality.

Two of the most widely used processes are thermoforming and rotational molding, each with specific characteristics, advantages, and applications depending on the thermoplastic materials used, design for manufacturability (DFM), and the required production cycles.

In this article, we explain the differences between both processes and help you decide which option best suits your production and design needs.

What is thermoforming?

Thermoforming is a plastic manufacturing process in which a plastic sheet is heated until it becomes flexible and then shaped over an aluminum, steel, or resin mold using vacuum or pressure.

This process is ideal for producing lightweight parts with surface detail in medium or low production runs, with vacuum forming being the most common technique.

Starting from a sheet conditions the types of feasible parts, which significantly limits its applications—for example, it is not possible to manufacture hollow parts or highly complex shapes.

What are the most common materials in thermoforming?

The most commonly used thermoplastics include PE, PP, ABS, and PVC, selected according to DFM requirements, chemical and UV resistance, and the surface finish needed for the part.

Choosing the right material ensures durability and functionality in specific industrial applications.

Advantages and limitations of thermoforming

Advantages:

-

Allows manufacturing with precise details within its geometric limitations and high-quality finishes.

-

Low mold cost compared to other industrial processes.

-

Suitable for medium or low production runs.

Limitations:

-

Not recommended for parts with thick walls or complex geometries.

-

Thickness variation in deep areas of the mold due to sheet stretching.

-

Lower mechanical strength compared to rotationally molded parts.

What is rotational molding?

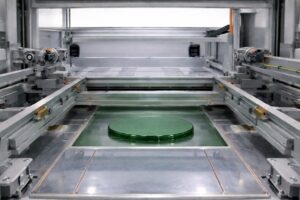

Rotational molding, or rotomolding, involves placing powdered plastic inside a hollow mold that rotates inside an oven. The material melts and coats the mold walls, forming hollow parts with uniform wall thickness.

This process is ideal for manufacturing even large, durable parts with a homogeneous finish, adapting to a wide range of industrial applications.

What are the most common materials in rotational molding?

Primarily polyethylene (PE), HDPE, and PVC are used, offering chemical resistance, UV resistance, and durability for demanding industrial environments.

The selection of the appropriate thermoplastic directly affects the durability and functionality of the final part.

Advantages of rotational molding

-

Produces parts across a wide dimensional range with uniform wall thickness.

-

Enables complex and customized designs (DFM optimization).

-

High mechanical and chemical resistance, ideal for industrial use.

-

Mold costs lower than injection molding for large parts.

Differences between thermoforming and rotational molding

| Factor | Thermoforming | Rotational Molding |

|---|---|---|

| Wall thickness | Variable, may be irregular | Uniform within tolerances |

| Part size | Small and medium | Small, medium, and large |

| Design complexity | Limited | High |

| Mold cost | Low–Medium | Medium |

| Production | Low or medium runs | Low to high runs |

| Product strength | Medium | High |

When to choose each process?

Thermoforming: Ideal for packaging, protective components, lightweight housings, and decorative panels, where surface detail is key and volumes are moderate.

Rotational molding: Recommended for tanks, containers, bodies, equipment components, urban furniture, etc., especially when uniform thickness, UV and chemical resistance, and hollow parts of various sizes are required.

You may also be interested in learning about the differences between rotational molding and plastic injection manufacturing.

Most common applications

Thermoforming: Packaging, trays, industrial housings, decorative panels.

Rotational Molding:

-

Automotive: Fuel tanks, covers, hollow structural components.

-

Agriculture: Irrigation tanks, fertilizer containers, hoppers, and agricultural equipment.

Read: Custom made plastic agriculture tanks

-

Energy and environment: Waste containers, water treatment systems, industrial vats and tanks.

-

Food and beverage: Liquid storage tanks, fermentation tanks, food product storage.

-

Chemical and pharmaceutical: Chemical-resistant containers, reagent storage tanks.

Learn more: Hiperbaric success case

-

Logistics and transport: Large containers, plastic pallets, diesel tanks, heavy-duty transport boxes.

-

Toys and urban furniture: Outdoor plastic furniture, playground modules, and recreational structures.

Factors to consider when choosing the technique

-

Manufacturing cost based on volume and part size.

-

Production cycles and availability.

-

Design for manufacturability (DFM) and part complexity.

-

Required wall thickness and mechanical, chemical, and UV resistance.

-

Sustainability and recyclability of thermoplastics.

Rotational molding at ABC Rotomoldeo

At ABC Rotomoldeo, we have extensive experience in manufacturing industrial parts using rotational molding, offering tailor-made solutions for industrial and commercial applications.

We advise on aluminum, steel, or resin mold design, thermoplastic selection (PE, PP, ABS, PVC, HDPE), and production cycle optimization, ensuring efficiency, quality, and durability in every project.

Do you have a project in mind? Contact our team and we will help you choose the most suitable manufacturing process, optimizing design, cost, and performance from the very first stage.